Morphotronik is the latest and most innovative print-and-verify unit for product serialization. Morphotronic works as an additional worker integrated within your existing lines.

A new coding and verifying system for pharmaceutical companies and CMO, designed for integration into manual packaging lines.

Products manually placed on the desk are picked up by the mechanic arm of the robot and coded through the printing station where they are printed with serialization information in the form of 2D barcodes, data matrix codes or text.

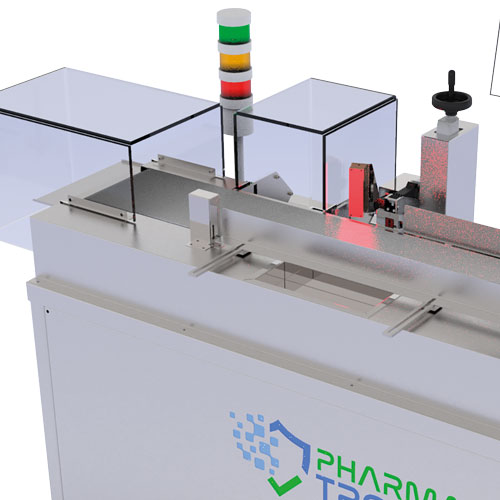

Subsequently, the arm presents serialized products to the camera that reads and checks according to ISO requirements and evaluated printing quality level.

Rejected product not properly coded are removed from the process and placed by the robot into the ejection station.

Serialized products are placed on the opposite side of the desk in order to let the next operator to pick them up for the next operations.

If needed, the robotic arm can place serialized products into a shipping case.

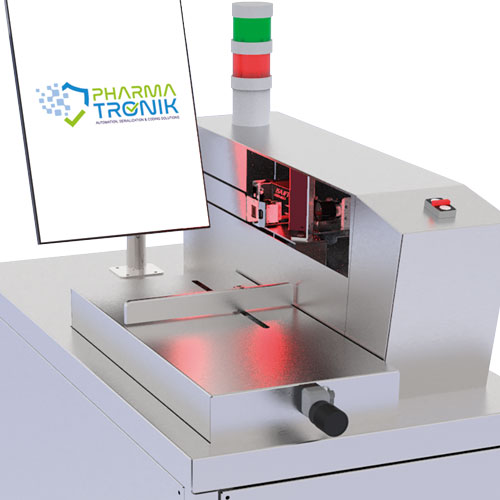

Morphotronik is equipped with a 15" touch screen that shows order details, statistical data and the captured images in a user-friendly layout.

Morphotronik can be customized according to customer’s requirements.

- Easy to install and maintain

- Emergency stop button

- Designed to work with different carton sizes (mm): up to W 180 x H 80 x D 140

- Printing area max (mm): W 150 x H 80

- Power supply: 220V/50Hz/10A

- Dynamic carton marking

- Printing, reading and verifying

- Printing Data Matrix and human readable elements according to EU requirements for serialization.

- Verifying and grading the printed information

- Visual feedback about serialization (OK/KO)

- Possibility to check the barcode, the quality grade of printing, and the reason for rejection (in case of bad cartons).

- It can be used also for decommissioning