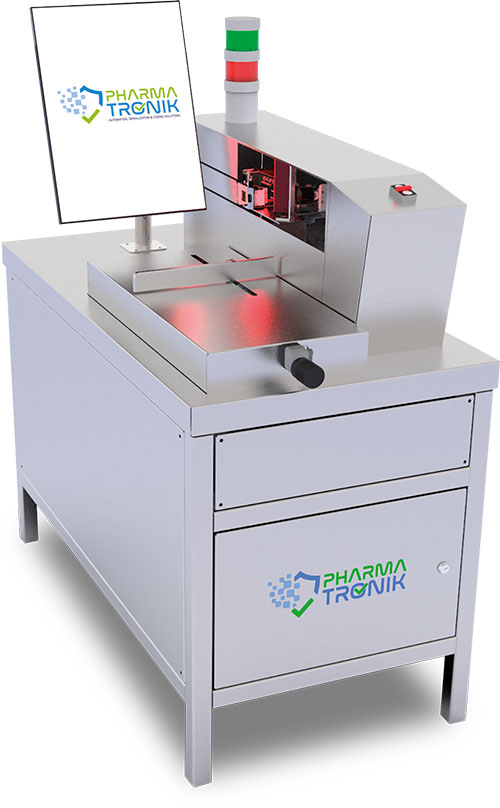

Manualtronik is the ultimate Pharmatronik's solution created to enable existing pharmaceutical packaging lines to easily meet compliance.

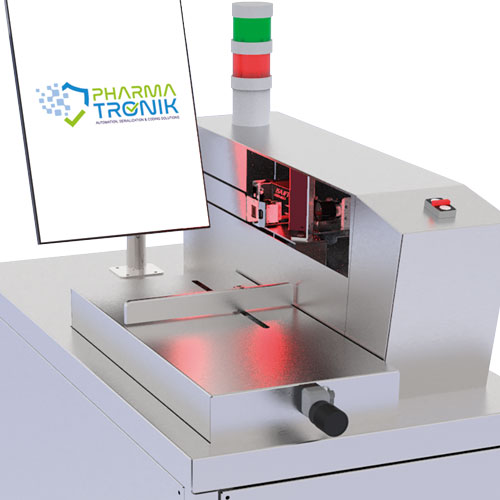

A manual station for printing and verification of products, ensuring accurate serialization identification.

Easy to use with only minimal training.

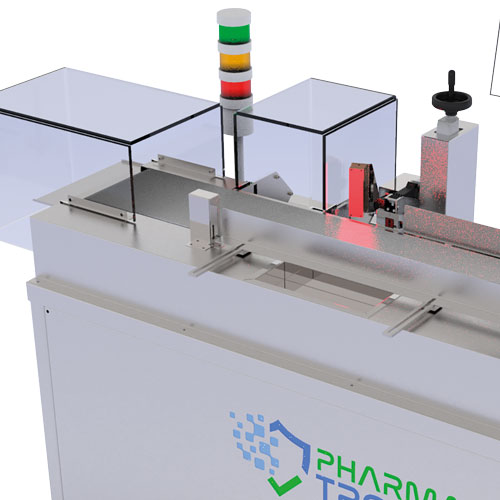

Manualtronik easily prints and verifies your cardboard boxes allowing you to perform manual serialization and aggregation.

An ultra-compact, fully-automatic unit designed to speed up the implementation process, helping you meet tight serialization deadlines.

Manualtronik can handle a wide range of carton sizes. Adjustable guides help position the cartons and ensure proper alignment of the desired printing area. Once the carton is in place, the operator has to only make a push/pull movement to print and inspect the code, obtaining as response an immediate feedback about if products were properly serialized or not.

The manual process is especially useful for safe handling of fragile products or for smaller batches.

You can choose to have the system generate serial numbers for you or you can upload them from an external software.

Like for every Pharmatronik's machine, the system also allows you to generate numerous reports: reconciliation, batch trail, photo archive.

Manualtronik provides all the necessary features to start up your serialized production, manage small or fragile batches and therefore increase your equipment step by step.

- Easy to install and maintain

- Conveyor system adjustable to front and back directions

- Designed to work with different carton sizes (mm): up to W300x H 300x 0400)

- Printing area max (mm): W 200 x H 125

- Power supply: 220V/50Hz/10A

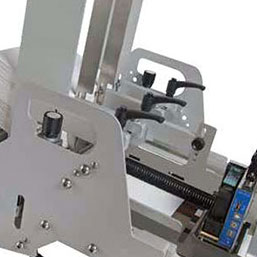

- Dynamic carton marking

- Printing, reading and verifying

- Printing Data Matrix and human readable elements according to EU requirements for serialization.

- Verifying and grading the printed information

- Visual feedback about serialization (OK/KO)