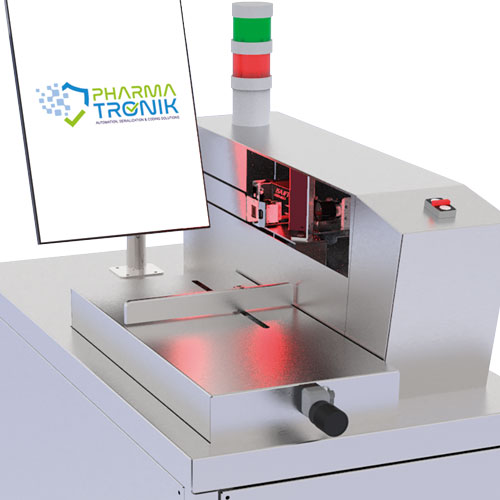

CodeTronik L is a fully-mechanic carton print-and-verify module for pharmaceutical packaging lines, which provides serialization of packaged products that can handle a wide range of carton sizes and doesn’t require air pressure system.

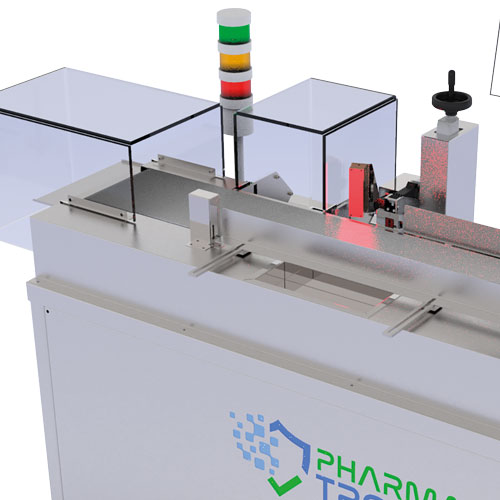

Products can be manually placed on the conveyor belt that transports them through the printing station where they are printed with serialization information in the form of 2D barcodes, data matrix codes or text.

The printed data is then read by the camera according to ISO requirements and printing quality level is evaluated. Rejected products not properly coded, are removed from the process at the ejection station.

CodeTronik L is equipped with a 15" touch screen that shows order details, statistical data and the captured images in a user-friendly layout.

CodeTronik L can be customized according to customer’s requirements.

- Easy to install and maintain

- The direction of the movement of the transport belt is from left to right (could be designed from right to left according customer’s requirements)

- Emergency stop button

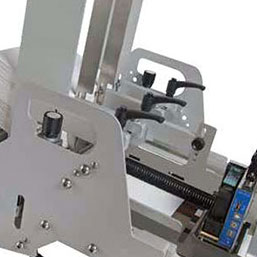

- Adjustable mounting kit for printing head an d camera

- Maximum production speed: up to 200 cartons/min (up to 60 m/min)

- Designed to work with different carton sizes (mm): up to W 400 x H 300 x D 400

- Printing area max (mm): W 300 x H 190

- Power supply: 220V/50Hz/10A

- Dynamic carton marking

- Printing, reading and verifying

- Printing Data Matrix and human readable elements according to EU requirements for serialization.

- Verifying and grading the printed information

- Visual feedback about serialization (OK/KO)

- Possibility to check the barcode, the quality grade of printing, and the reason for rejection (in case of bad cartons).